GPS use in Tower crane group anti-collision system

1. Scope of application:

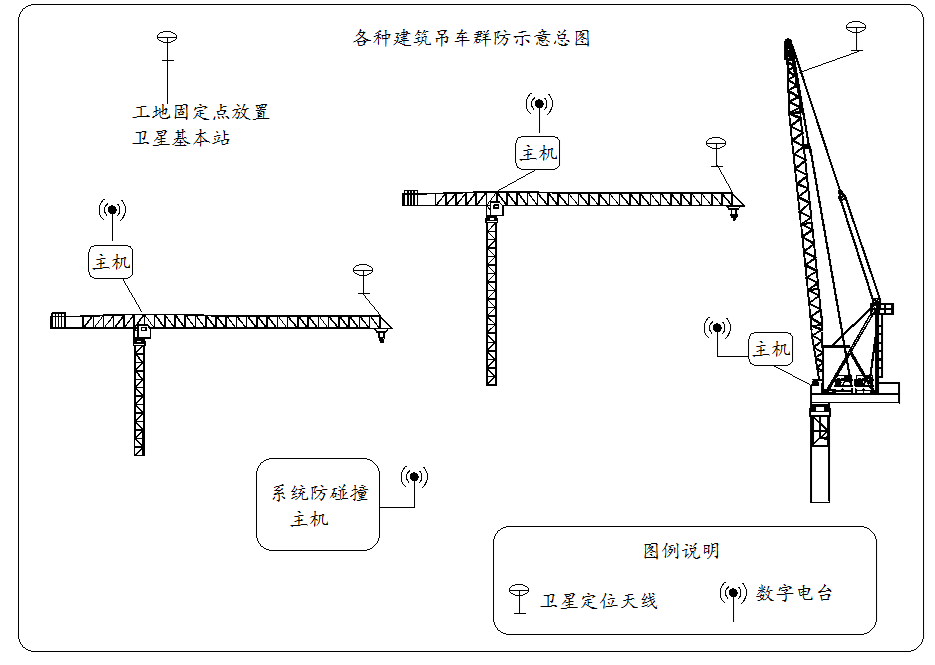

This tower crane cluster anti-collision system is specially designed for the monitoring and safe anti-collision between various engineering machinery and buildings in construction sites. Monitor whether various tower cranes are in safe working condition, and at the same time, whether there is a possibility of collision between construction machinery.

In this system, the status of all construction machinery within a radius of 2 kilometers (including: the amplitude, height, weight of the hoisted object, the elevation angle of the boom relative to the horizontal plane, the rotation angle of the boom, wind speed and other parameters related to the crane) are processed through Calculate and provide early warning to avoid collisions between cranes and cranes and between cranes and buildings. Once the tower crane enters the dangerous area, a control signal will be sent immediately to prohibit the tower crane from traveling into the dangerous area. Play the role of anti-collision protection.

Tower cranes within the group anti-collision range can be flat-head tower cranes, hammer-head tower cranes, luffing tower cranes, truck cranes, crawler cranes and other cranes. At the same time, anti-collision systems can also be added to surrounding buildings and other buildings that are likely to collide. Such as buildings, power towers, etc.

2. The biggest features of this product

A. Using GPS satellite positioning technology, various cranes can accurately locate their azimuth, position, and altitude during movement, with a position accuracy of up to 20cm.

Currently, most manufacturers use low-end electronic compasses to detect the angle of the Earth's magnetic field lines, compare and calculate the azimuth of the vehicle body, and thus calculate the position and orientation of the vehicle body. This electronic compass detects the Earth's magnetic field, which is a weak electromagnetic signal. Once there is interference around the compass, such as engine start stop, presence of human body or other magnetic fields. At this point, even small disturbances can cause inaccurate measurements, and the calculated position of the vehicle body based on this data will have even greater errors.

So, using satellite positioning directly for positioning has obvious advantages, reliability, and safety.

B. Using a digital radio module to transmit various data, this module adopts advanced DSP technology internally, which is stable and strong in anti-interference. The transmission baud rate can reach 19200 or even higher, with a large amount of data. The transmission distance can reach up to 25 kilometers, which is far and much longer compared to other types of transmission modules. Ensuring fast positioning and real-time transmission.

The above two unique technologies fully guarantee the accuracy of the on-site collision prevention system.

C. The height and amplitude measurement module adopts an electronic encoder specifically designed for construction machinery. This encoder is a 65535 turn absolute value encoder. This encoder is connected to the center axis of height and amplitude, and detects the angle of rotation through the rotation of the winch, thereby calculating the magnitude of height and amplitude. This electronic encoder can detect a 0.1 ° angle change, with a corresponding height amplitude accuracy controlled within 1cm.

3、 Detailed anti-collision plan:

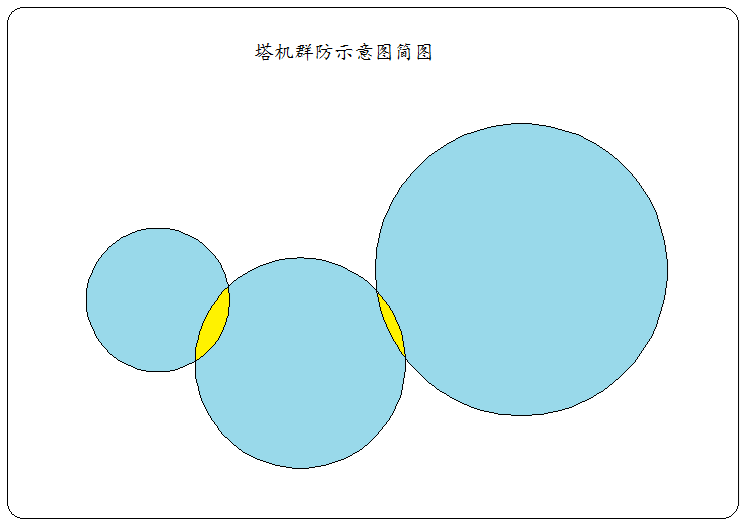

3.1 Tower crane group anti-collision diagram (which types of anti-collision)

3.2.2 System anti-collision host

3.3 What collisions can be prevented by the system

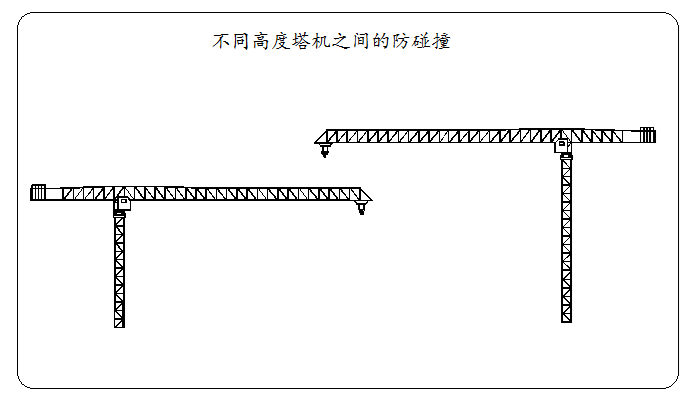

3.3.1 Anti collision between tower cranes of different heights

2.3.2 Collision prevention between different types of tower cranes

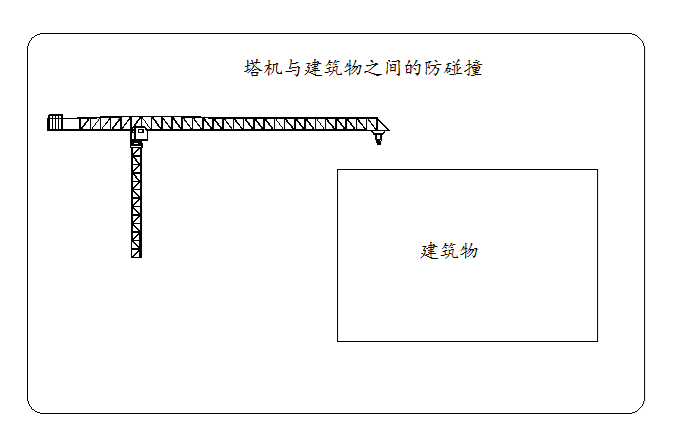

2.3.3 Collision prevention between tower cranes and buildings

4、 Parameters of each part

4.1 Torque limiter (this instrument is installed on a single crane)

4.1.1 Torque limiter host

Model:AN-T01

Supply voltage: DC9-36V or AC220V or AC 380V

Display: 7 inches (480 * 800) Operating temperature: -20 to 70 degrees Celsius

Interface: 12 control interfaces+CAN2.0+3 232 serial ports+485

Mainly specific:

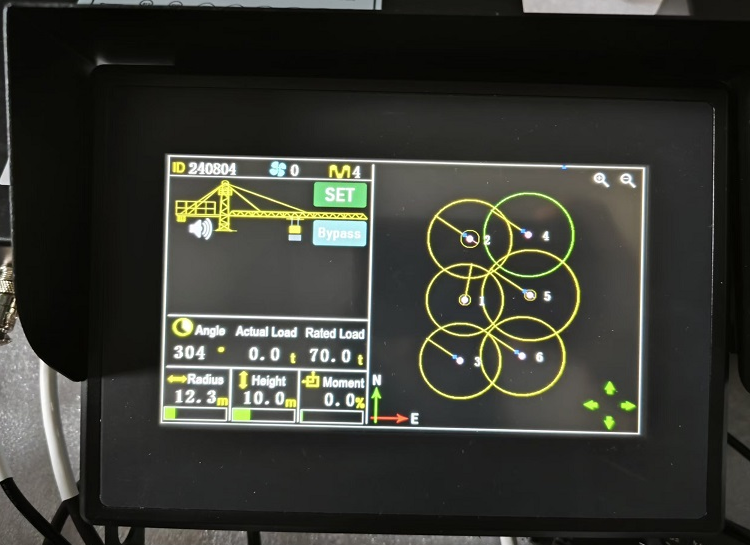

1. Real time display: Display the current working parameters in real-time through graphics and numerical values, including lifting capacity, torque

Amplitude, rotation angle, and lifting height;

2. Critical alarm: When the lifting capacity and lifting torque exceed 90% of the rated value, an automatic sound and light alarm will be issued

3. Overload power outage: When the rated load is exceeded, the system automatically cuts off the working power supply in the dangerous direction, forcing the termination of illegal operations;

4. Data record download: It meets the full working parameter record requirements of GB/T5031-2008 and can be downloaded using a USB flash drive. The instrument can store at least 6 months of historical records;

5. Area restriction: The hook can be prevented from entering the restricted working area through preset parameters, achieving the function of avoiding fixed obstacles;

6. Group defense function: It can communicate with surrounding tower cranes to obtain the position, left side, and orientation of nearby tower cranes, and send out control signals before colliding with them.

7. Remote management: tower crane working data can be transmitted through wireless network and Internet, and can be viewed and managed in real time through authorization. At the same time, it can receive data transmitted by the platform, achieve remote control of instruments, and achieve the goal of controlling the operation of the entire vehicle.

4.1.2 Anemometer

This anemometer can detect the wind speed around the crane. There are mandatory regulations in the domestic crane manual that lifting operations must be stopped if the wind level exceeds a certain threshold.

4.1.3 Height and amplitude sensors

The height and amplitude sensors are collected using an absolute value encoder. This sensor is non-contact and specially developed by our company for the construction machinery industry. It has high precision and strong anti-interference ability, with an absolute accuracy within 0.2 meters. At the same time, installation is also very convenient and does not require welding on the vehicle body.

The same industry uses turbine worm type sensors, and the absolute accuracy will definitely be beyond 0.6 meters, with significant errors.

4.2 Communication module

Model: CDP Data Transmission Radio Power: 5W

Communication frequency: 19200 baud rate interface: 232 serial port

Transmission distance: 5-25 kilometers, configurable temperature range: -40 ℃ to+70 ℃

Humidity range: 95% @ 40 ℃ Non condensing

Features: This radio station adopts DSP technology, which far exceeds analog data transmission radio stations in terms of working stability, transmission reliability, anti-interference ability, transmission speed, and transmission distance. The radio station adopts a transparent transmission protocol and does not require special programming settings. Any common asynchronous communication protocol can be used.

It can also be used under the harshest environmental conditions. The work radio station has excellent design and performs well in environments with severe interference and blocked transmission paths. The radio station requires a wide operating range for temperature and power supply.

4.3 Anti collision server

The tower crane group defense server can handle collision warning and control for 8 cranes simultaneously on time. It can calculate whether it is safe based on the position and direction information of the crane transmitted back by the torque limiter on each crane, as well as the position of objects with collision risks such as buildings and high-voltage lines on site. Before there is a possibility of collision danger, issue an alarm and control the torque limiter of the responding tower crane to prevent collision from occurring.

Contact: Wang Jin

Phone: Sales manager 13697297875

Tel: Technical support 13908600829

Email: 651673556@qq.com

Add: No.6 Bayi Road, Wujiagang District, YiChang City, Hubei Province, China

<sup id="j7485"></sup>